4-D Rheo-SANS

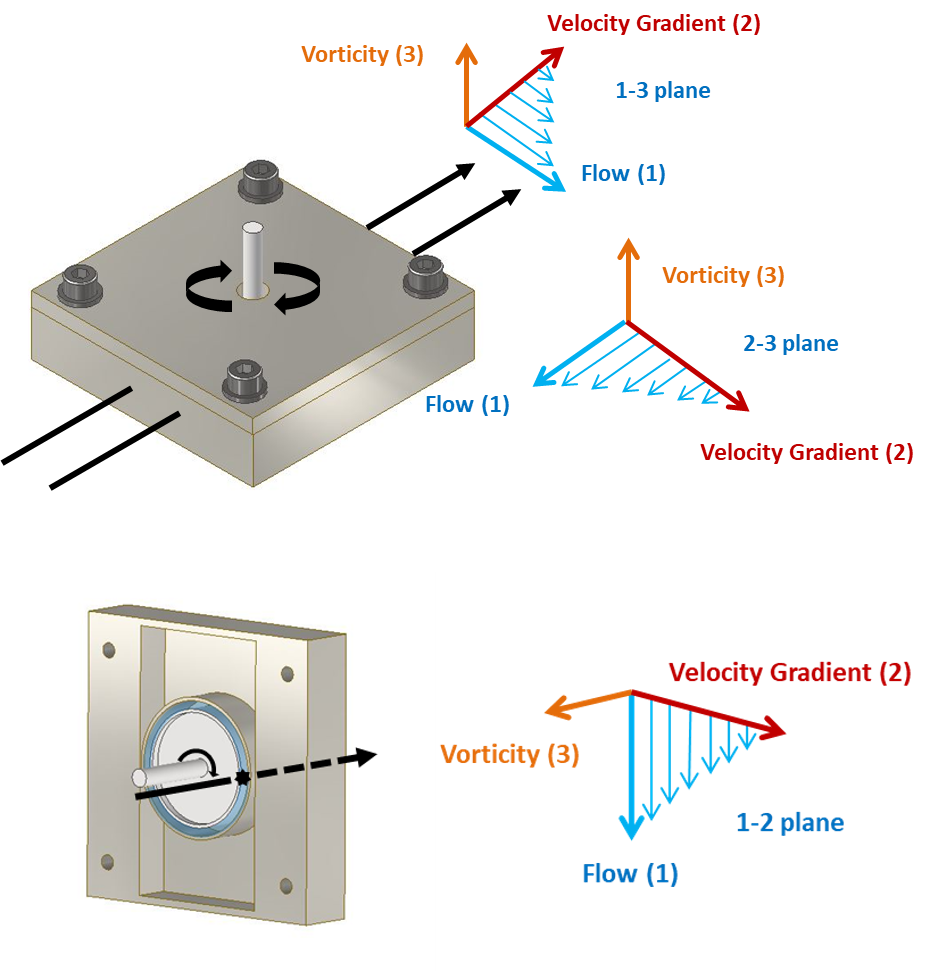

With support from a Department of Energy STTR Phase II award (DE-SC0019595), we are develoing the first, true Rheo-SANS sample environment capable of performing in all three planes of flow and with a single sample loading. This instrument will offer unprecedented ease of use and integration to enable simultaneous rheological and structural measurements on soft matter (i.e., polymers, complex fluids, nano and colloidal solutions, coatings and inks) and biological materials (i.e., drug delivery, hydrogels, tissue engineering). Please click Contact Us to obtain updated information on this instrument and/or discuss your measurement needs.

Interfacial Rheology + Neutron Reflectivity

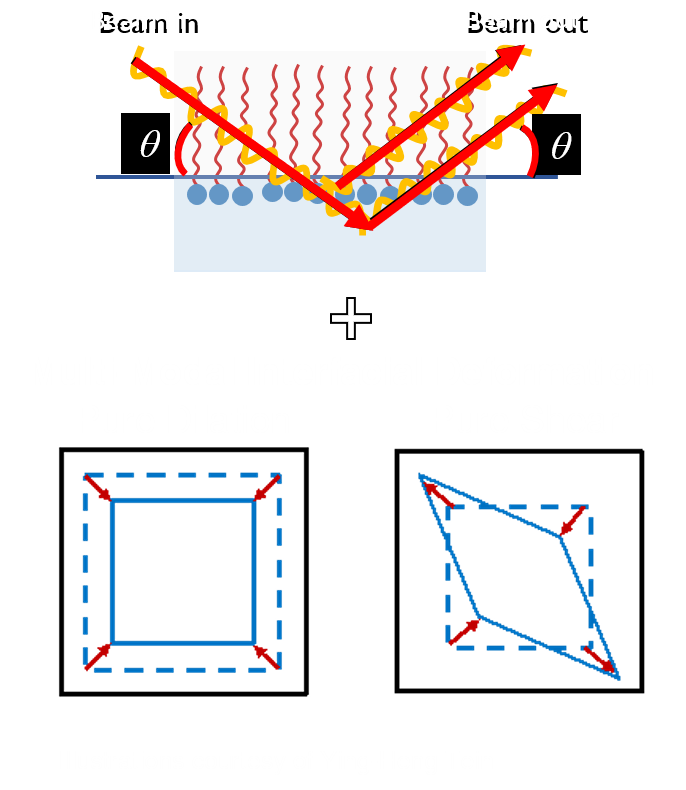

With support from a Department of Energy STTR Phase I award (DE-SC0020534), we are developing a world-leading sample environment for neutron scattering applicable to a broad range of complex fluid and biological interfaces under shear fields and processing conditions. This sample environment directly addresses the unmet need for simultaneous measurement of interfacial stresses and microstructure across a broad range of material properties, and conditions. The sample environment has broad utility for the soft-matter and biological neutron scattering user community, and is equally critical for research in materials processing, with broad, industrial R&D use in pharmaceuticals, foods, paints/coatings, consumer products, and more.

Please Contact Us to learn more and discuss your measurement needs.

High Throughput High Pressure SANS

With support from a NIST SBIR Phase I award, we are developing the only high hydrostatic pressure sample environment for small angle neutron scattering that enables high throughput structural measurements with temperature and pressure control that is integrated with beamline data acquisition software. This sample environment will greatly improve both the ease of use of high pressure SANS sample environments and greatly increase the throughput on the beamline while minimizing effort by instrument scientists and engineers. High-pressure processing is a valuable tool for applications that include rapid vaccine development and the improvement of food and pharmaceutical shelf life.